Discover how cost efficiency enhances strategic value in global manufacturing, driving competitiveness and unlocking new growth opportunities across industries.

India as an alternate for U.S. Manufacturers

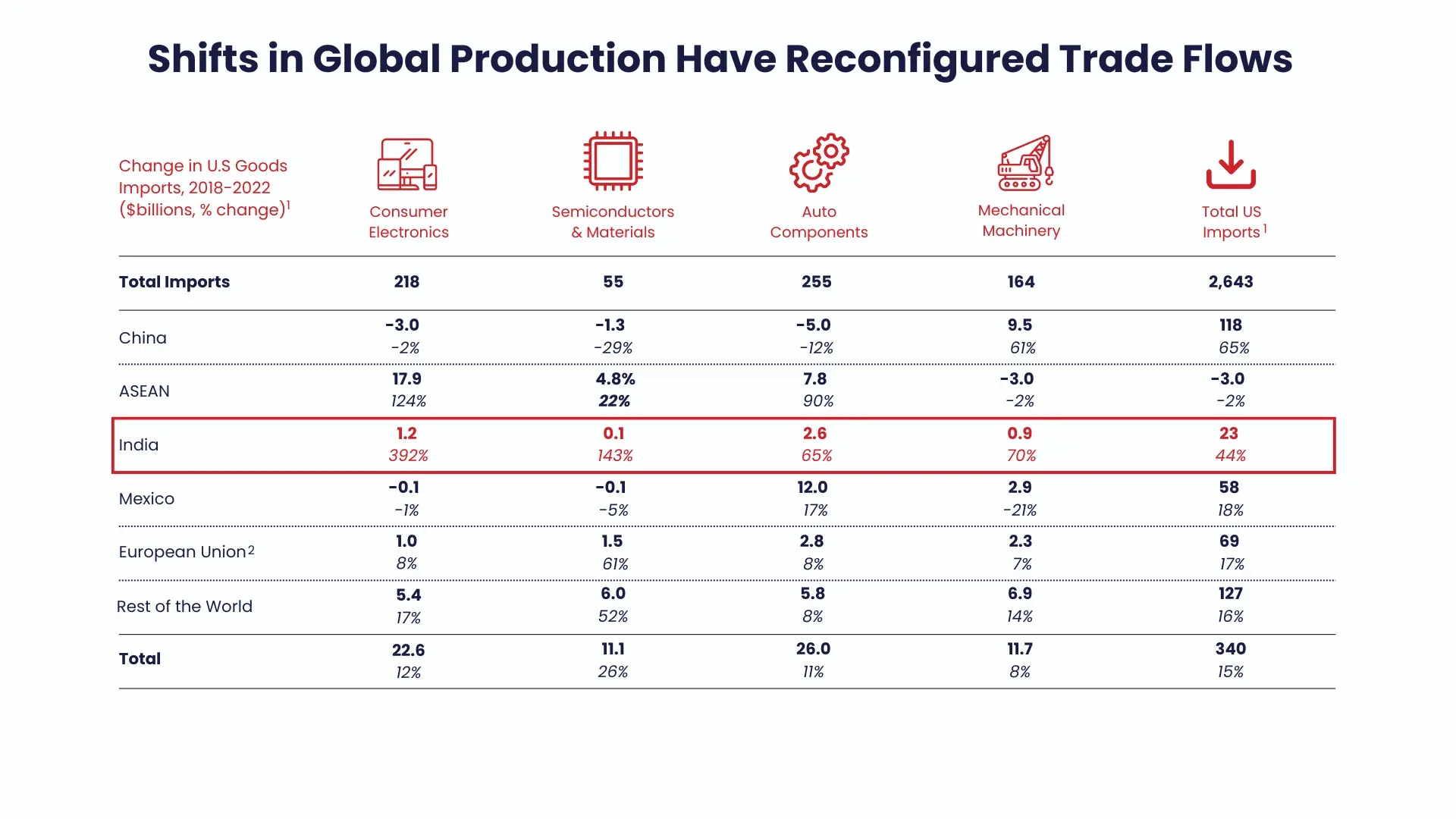

As the global manufacturing landscape is evolving, U.S. manufacturers are rethinking their reliance on China due to geopolitical tensions, rising labor costs, and supply chain disruptions. India, with its growing manufacturing sector and skilled talent pool, presents a compelling alternative.

Source: BCG- Harnessing the Tectonic Shifts in Global Manufacturing

Cost Efficiency

India offers significant cost savings compared to Western countries. Lower labor costs and government incentives make it an attractive destination for cost-sensitive projects. According to the Boston Consulting Group (BSG), manufacturing costs in India are 10-20% lower than those in the U.S., making it a cost-effective option for many industries.

![]() Case Study: A small family-owned hardware business in the USA faced high costs due to small order quantities. By utilizing a manufacturing platform to connect with cost-effective suppliers in India, they achieved lower minimum order quantities. This strategy resulted in significant cost savings while ensuring quality and establishing a reliable supply chain.

Case Study: A small family-owned hardware business in the USA faced high costs due to small order quantities. By utilizing a manufacturing platform to connect with cost-effective suppliers in India, they achieved lower minimum order quantities. This strategy resulted in significant cost savings while ensuring quality and establishing a reliable supply chain.

Skilled Workforce

India has a vast pool of engineers and skilled labor, facilitating complex manufacturing processes and seamless communication. The country produces over 1.5 million engineering graduates annually, supporting a diverse range of industries from IT to heavy engineering.

Growing Domestic Market

India’s expanding middle class represents a robust domestic market for manufactured goods. McKinsey & Company estimates that by 2025, India will be the third-largest consumer market, offering significant growth opportunities for businesses.

Government Support

Initiatives like 'Make in India' offers substantial incentives and support to foreign investors. The Indian government offers tax breaks, subsidies, and simplified regulatory processes, to attract foreign investment, thereby making it an attractive avenue for manufacturing operations.

Source: Scope of Business and Investment Opportunities under Make-in-India

Risk Mitigation

Diversifying supply chains to India reduces dependency on a single country, mitigating risks associated with geopolitical instability and trade disputes. This strategic diversification helps companies maintain continuity in their operations even amidst global disruptions.

![]() Case Study: An aerospace company faced challenges in sourcing additional suppliers for parts within tight deadlines. Utilizing a manufacturing platform, they connected with a supplier ecosystem in India to enable local procurement and manufacturing. This strategic collaboration highlighted the importance of local partnerships, resulting in enhanced cost savings and project efficiency.

Case Study: An aerospace company faced challenges in sourcing additional suppliers for parts within tight deadlines. Utilizing a manufacturing platform, they connected with a supplier ecosystem in India to enable local procurement and manufacturing. This strategic collaboration highlighted the importance of local partnerships, resulting in enhanced cost savings and project efficiency.

Cost Savings: Key Areas

Labor Costs

India's average manufacturing labor cost per hour is significantly lower than that of the U.S. and other Western countries. For example, automotive manufacturers are increasingly shifting production to India to take advantage of these lower wage rates. This strategic move not only enhances profitability but also helps diversify production risks across different regions, making companies more resilient in a global market.

Operational Costs

Lower utility costs, real estate, and operational overheads are additional advantages. The Indian government often provides tax breaks and incentives for foreign companies, further reducing expenses.

![]() Case Study: An industrial machinery company with excess inventory needed to identify suitable buyers for liquidation. A manufacturing platform facilitated connections with potential buyers, enabling efficient inventory management and reducing holding costs. This strategy improved cash flow and streamlined their operations.

Case Study: An industrial machinery company with excess inventory needed to identify suitable buyers for liquidation. A manufacturing platform facilitated connections with potential buyers, enabling efficient inventory management and reducing holding costs. This strategy improved cash flow and streamlined their operations.

Raw Material Costs

Abundant natural resources in India reduce raw material costs, thereby keeping production costs low. This not only reduces supply chain costs but also supports the local economy and mitigates risks associated with exchange rate fluctuations.

Logistics and Supply Chain

India’s strategic location and improving logistics infrastructure help reduce shipping and logistics costs. Better connectivity through an expanding network of roads, railways, and ports facilitates efficient movement of products and components.

![]() Case Study: A consumer goods startup aimed to cut high import costs by seeking a local market entry strategy. Collaborating with a manufacturing platform allowed them to connect with local suppliers for procurement and assembly, integrating their patented technology and emphasizing the value of local partnerships.

Case Study: A consumer goods startup aimed to cut high import costs by seeking a local market entry strategy. Collaborating with a manufacturing platform allowed them to connect with local suppliers for procurement and assembly, integrating their patented technology and emphasizing the value of local partnerships.

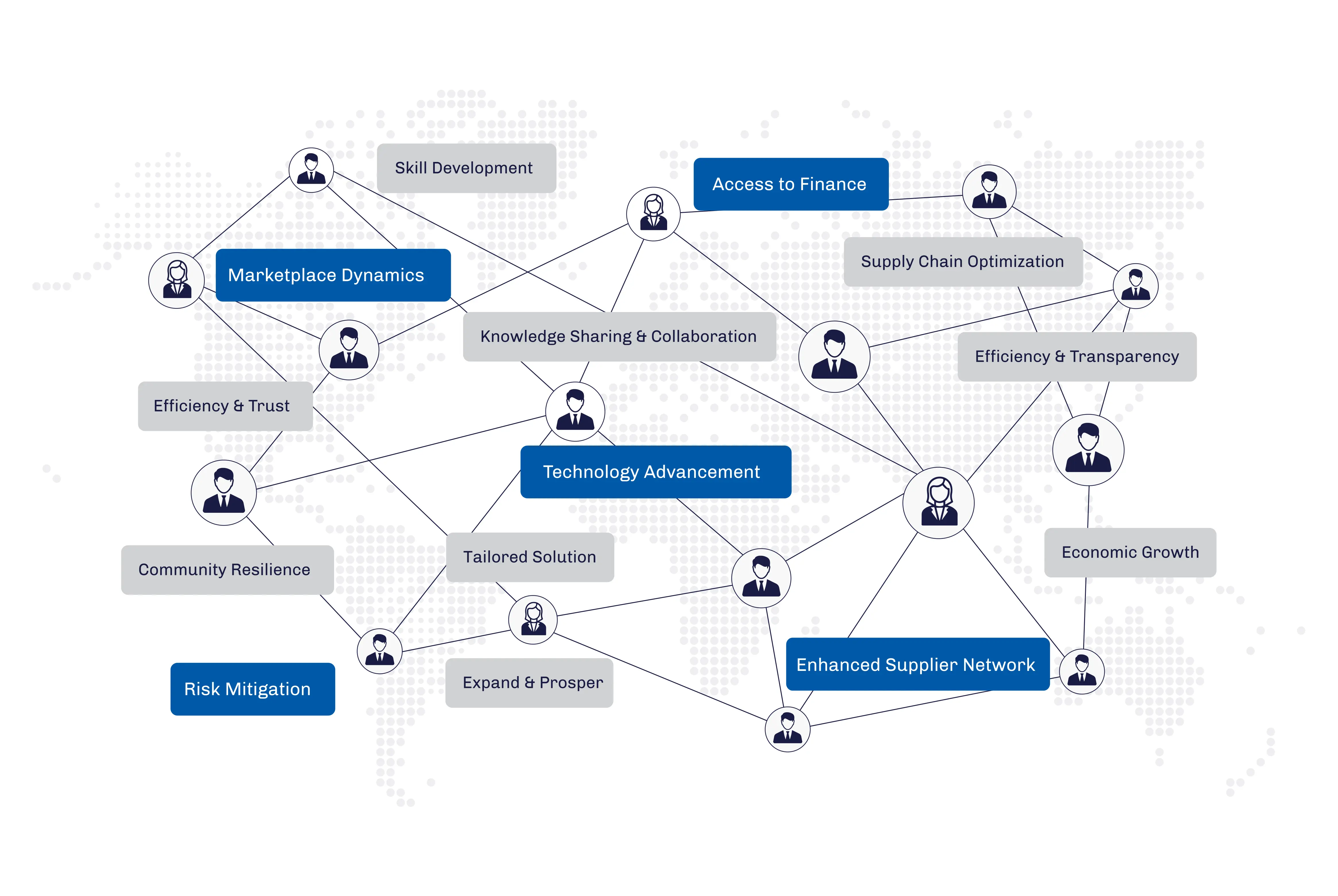

How can platforms help in your journey?

Manufacturing platforms play an important role in connecting U.S. manufacturers with suitable suppliers in India, facilitating smoother operations and driving cost efficiencies.

-

Efficient Supplier Matching: Advanced algorithms match U.S. manufacturers with suitable Indian suppliers based on production capabilities and quality standards.

-

Streamlined Communication: Integrated tools facilitate seamless interaction, ensuring clarity and prompt resolution of issues.

-

Risk Mitigation and Compliance: Comprehensive due diligence and compliance checks reduce risks of non-compliance and associated costs.

-

Logistics and Supply Chain Optimization: Tools for tracking and optimizing logistics minimize shipping times and costs.

Source: Cnerzy

India's growing manufacturing sector presents significant cost savings and risk mitigation opportunities for U.S. manufacturers. By leveraging platforms Cnerzy, companies can efficiently navigate the challenges and build strong, long-term partnerships, unlocking the full potential of India's manufacturing capabilities.

Connect with us at marketing@cnerzy.com

Source:

- Embracing Design as a Core Tenet of Make in India Will Build Trust in Indian Manufacturing- The Economic Times

- How India Is Emerging as a Production Hub for Global Exports - Forbes

- India's Low Labour Costs Key in Wooing Firms to Move Production from China- Business Standard

- Harnessing Tectonic Global Shift in Manufacturing- Boston Consulting Group (BCG)

- Comparison between India and USA Market - ResearchGate