How Prototyping Partnerships Works

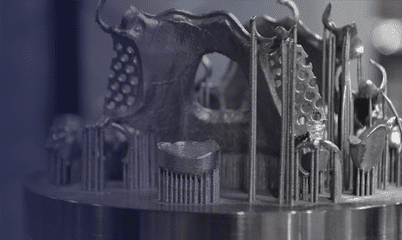

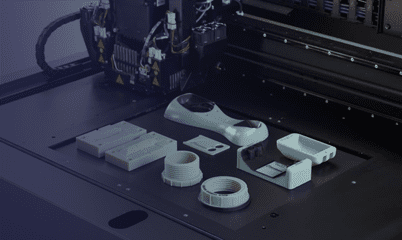

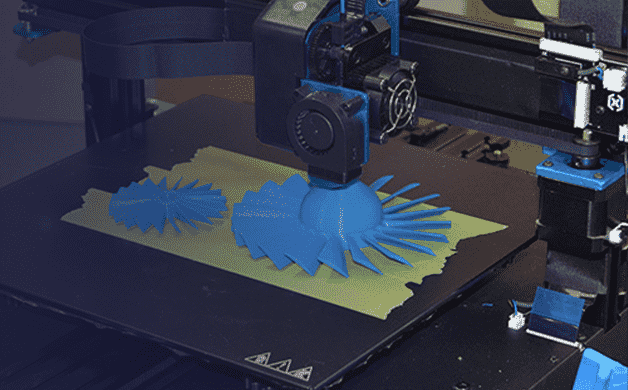

The next stage of design conceptualization involves prototyping, a crucial step in product development.

Prototyping partnerships operate by leveraging rapid prototyping techniques, emphasizing speed and

cost-effectiveness.

This approach allows for swift iteration and informed design decisions before

functional testing and production stages. By collaborating with reliable suppliers, you gain access to

diverse rapid prototyping capabilities, expediting product development and delivering quality

prototypes.

This process ultimately reduces cycle times and enhances long-term manufacturing solutions.