How Precision Manufacturing Works

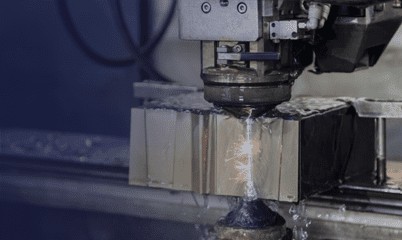

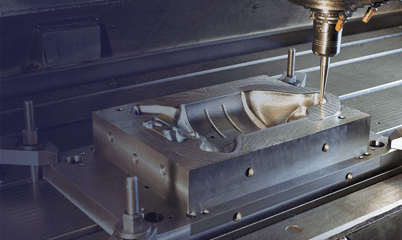

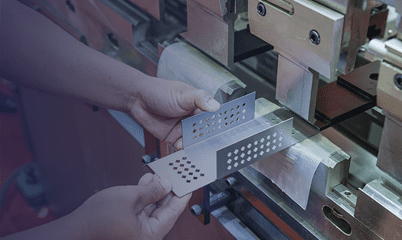

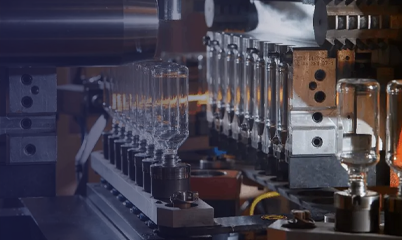

We help seamlessly transition your prototypes into production with our supplier network. Get precision

machined parts manufactured with superior accuracy, finish, and speed.

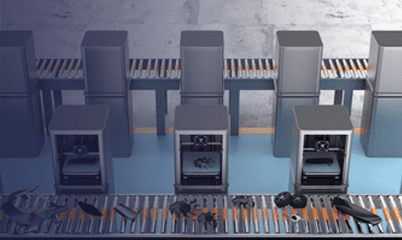

Small or large batches, fulfill

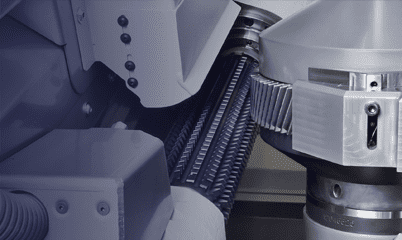

all your production needs with our comprehensive range of manufacturing services, covering CNC

machining, casting, forging, fabrication, and injection molding techniques.