From real-time data to predictive analytics, digital platforms empower supply chains, driving productivity and resilience.

Leveraging Digital Platforms for Supply Chains

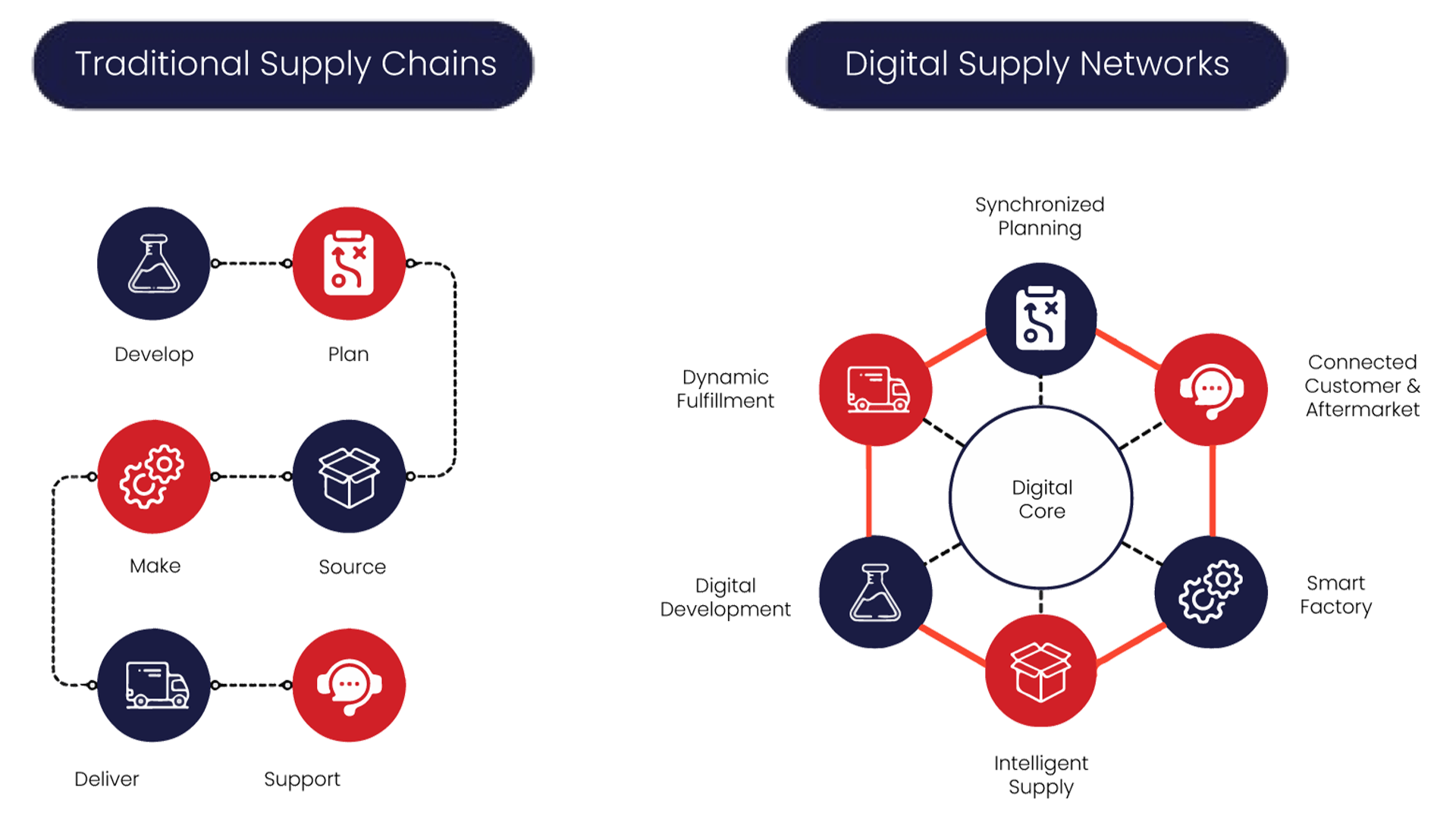

Digital platforms are revolutionizing supply chain management by leveraging digital technologies. These platforms help businesses overcome challenges and streamline operations for sustainable growth. Traditionally, Supply Chain Management (SCM) depended on the precise coordination of logistics, operations, and supplier relations to meet the evolving consumer demands, while the pandemic and geopolitical tension underscored the need for greater visibility to manage disruptions effectively. Today, manufacturers face fluctuating demands, strict regulations, and increasing expectations for sustainability, pushing them to adopt faster and cost-effective solutions to remain efficient and responsive in the competitive landscape, and prioritize customer needs and foster collaborative partnerships

Source: Supply Chain Technologies to Open New Business Possibilities

The Future of Supply Chain Management with Digital Transformation

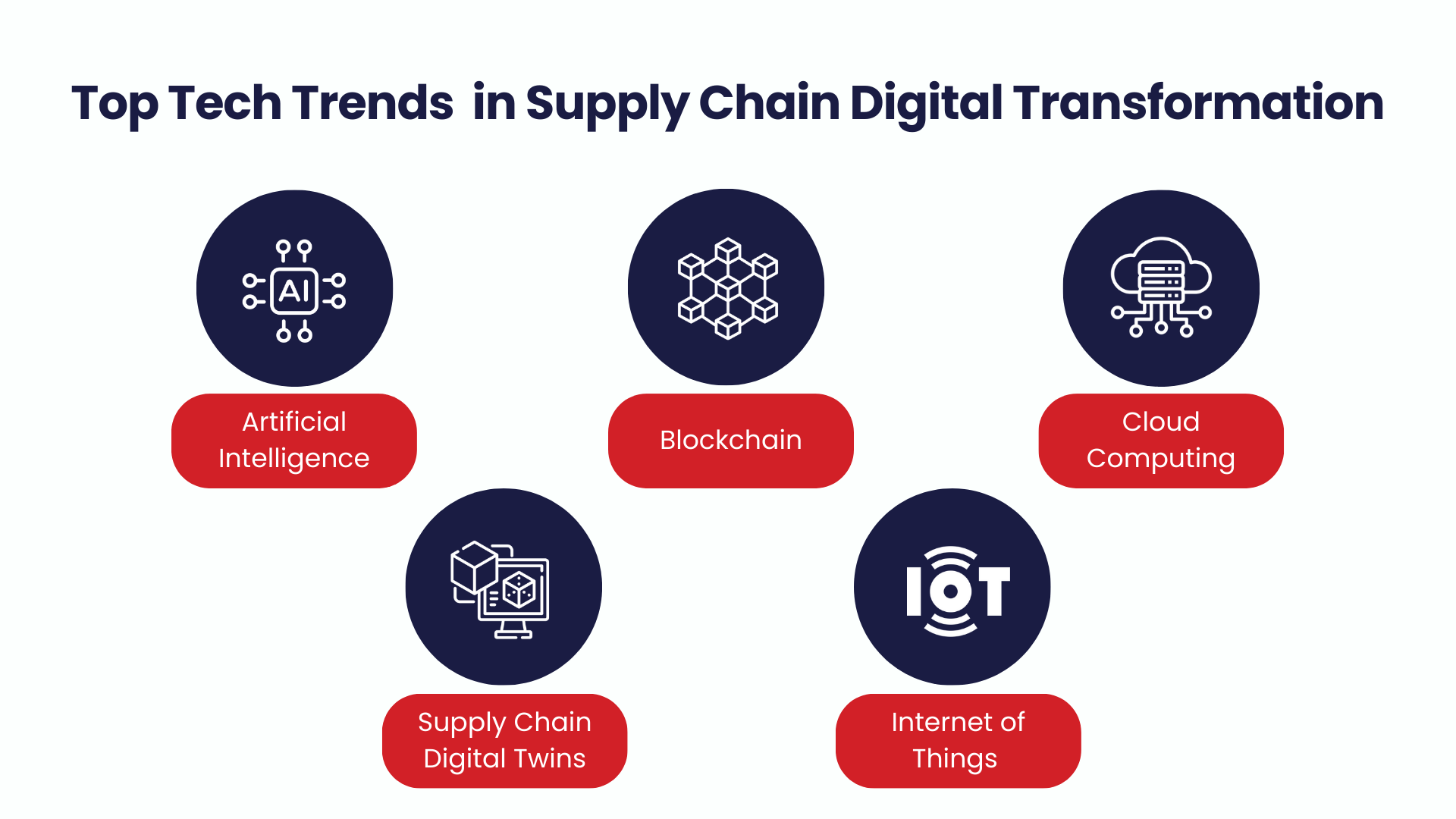

Digital transformation offers a compelling solution by integrating cutting-edge technologies like Artificial Intelligence (AI), the Internet of Things (IoT), Big Data Analytics, and Cloud Computing to optimize supply chain processes focusing on key performance indicators (KPIs) for real-time visibility, effectiveness of automated processes, along with customer satisfaction, loyalty, and retention

Source: Supply chain Digital Transformation

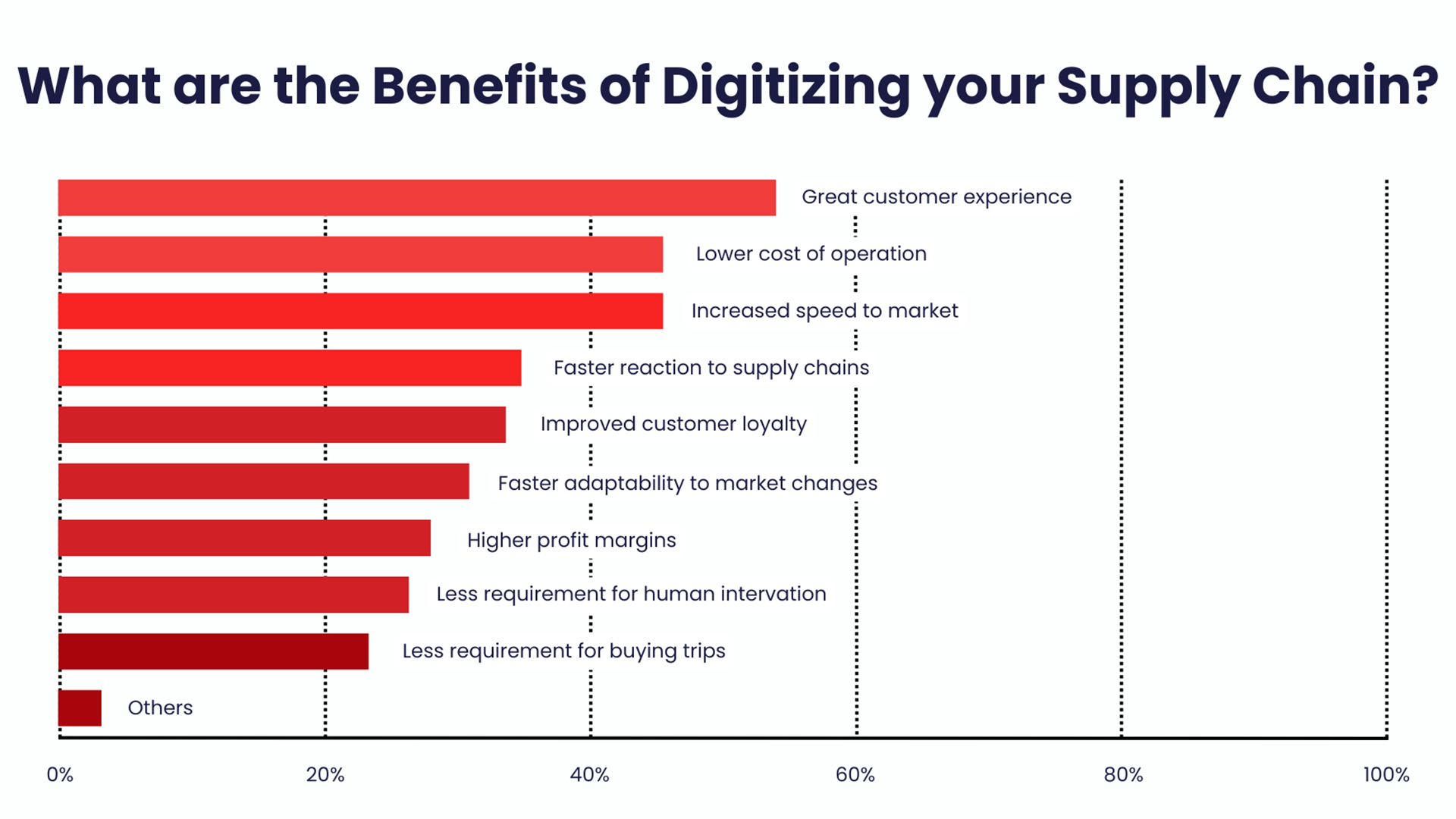

- Increased Transparency and Customer Satisfaction: Digital solutions enhance transparency and customer satisfaction through real-time updates and order tracking

- Improved Resilience and Risk Management: Predictive analytics help foresee potential issues and develop effective mitigation strategies, enhancing the supply chain's resilience to disruptions

- Enhanced Efficiency and Productivity: Automation speeds up workflows and cuts operational costs, allowing companies to allocate resources more effectively

- Streamlined Supplier and Partner Collaboration: Improved communication and collaboration facilitate synchronized operations and real-time data sharing.

Role of Digital Platforms in Supply Chain

Digital platforms act as centralized hubs connecting suppliers, manufacturers, distributors, and retailers to improve communication and collaboration, with features like demand forecasting, inventory optimization, production planning, order management, and logistics tracking.

- Real-time Data Integration: Accurate, up-to-date information for better decision-making. A report by Accenture highlights that real-time data integration can reduce lead times by 30%.

- Enhanced Collaboration and Visibility: Improves coordination and transparency across the supply chain. A survey by KPMG, 70% of supply chain leaders believe that visibility is critical to the future success of their operations

- Predictive Analytics and Prescriptive Insights: Anticipate market trends and optimize operations. McKinsey notes that predictive analytics can reduce inventory levels by up to 30% while maintaining high service levels

- Demand Sensing and Forecasting: Enables precise demand planning and inventory managemen

The Power of Leveraging Digital Platforms

Digital transformation in manufacturing and supply chains, driven by e-commerce growth, especially in the B2B sector, has made processes faster, more efficient, and cost-effective, while expanding global access to customers and suppliers.

Source: Overcoming Challenges by Implementing Digital Technology in Supply Chain

- Convenience: Simplified product search, comparison, reviews and streamlining procurement. Forrester Research shows that 60% of B2B buyers prefer digital platforms for their convenience and comprehensive offerings

- Streamlined Procurement: Advanced tools save time and resources by simplifying purchasing workflows. IDC reports that companies using digital procurement platforms can reduce procurement costs by up to 30%.

- Competitive Pricing: Digital platforms enhance price transparency and competitiveness. PwC found that these platforms improve cost savings by giving access to a wider range of suppliers and products

- Enhanced Product Selection: Digital platforms provide access to a vast selection of products and services from multiple suppliers.

- Integration and Analytics: Integration with accounting and data analytics offers valuable insights. BCG reports that companies using integrated digital solutions see a 25% increase in supply chain efficiency.

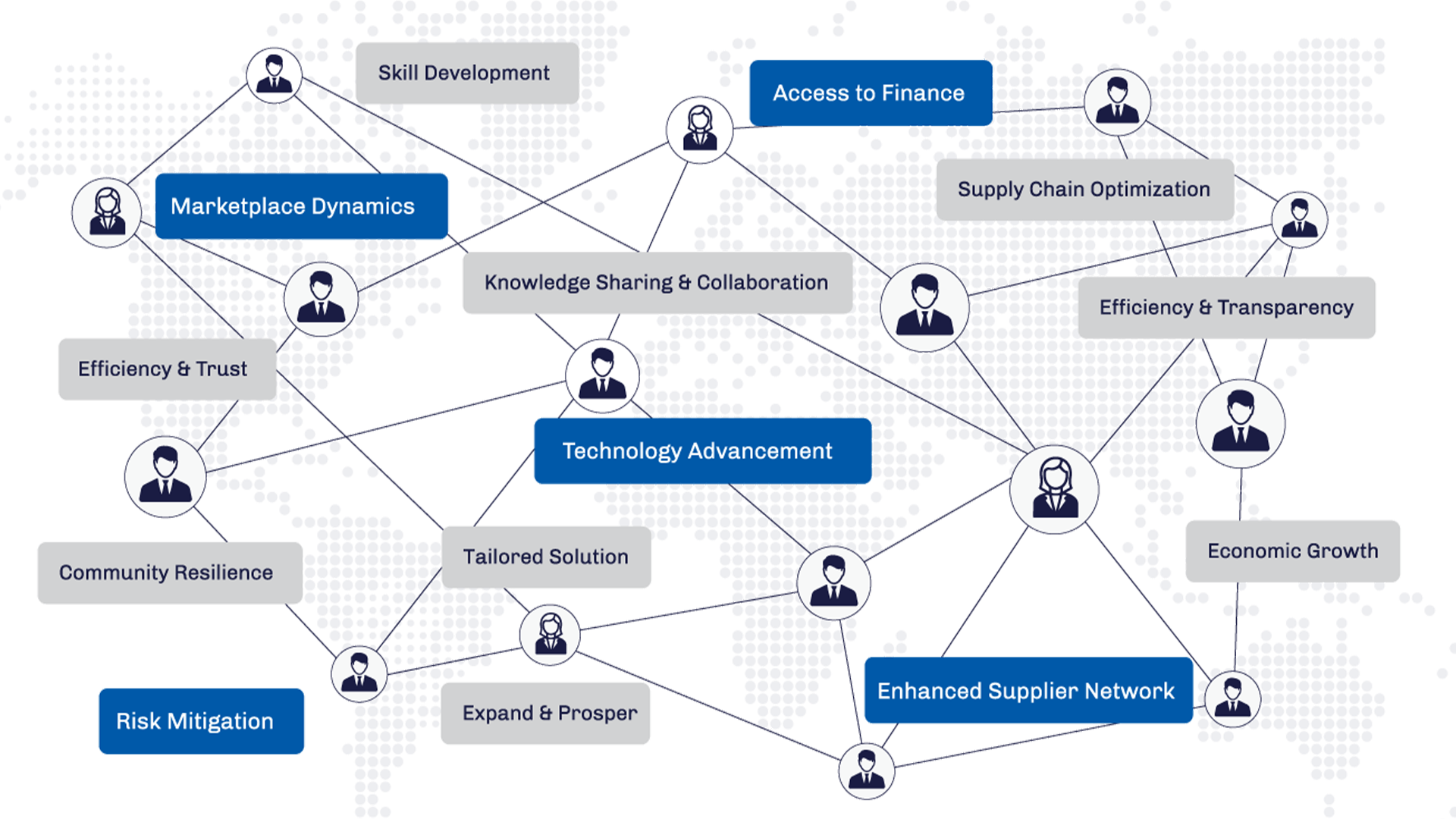

Cnerzy's Role in the Evolving Supply Chain Landscape

Source : Cnerzy- Empowering Manufacturing Ecosystem

In today’s dynamic market, digital platforms like Cnerzy leverage technology to boost efficiency and collaboration in manufacturing. As a community-centric platform, Cnerzy connects SMEs to address design and production challenges, ensuring quality partnerships through rigorous supplier evaluations, industry expertise, and timely deliveries. Built on the pillars of Business, Finance, Skills, and Technology, it employs AI/ML to streamline processes from lead generation to cash collection, enhancing overall business operations.

Connect with us at marketing@cnerzy.com.

Sources:

- McKinsey & Company, "The Digital Supply Chain’s Missing Link: Focus"

- Gartner, "Top Strategic Supply Chain Technology Trends"

- Deloitte, "Supply Chain Digital Transformation: Enhancing Efficiency and Resilience"

- Capgemini, "The Digital Supply Chain’s Missing Link: Focus"

- Forrester Research, "The State of Digital Business 2023"

- IDC, "The Business Value of Digital Supply Chain Transformation"

- PwC, "Digital Supply Chains: A New Era of Efficiency"

- Boston Consulting Group (BCG), "The Digital Imperative in Supply Chain"

- Accenture, "Supply Chain Reinvention: Digital Transformation"

- KPMG, "Global Manufacturing Outlook: Supply Chains of the Future"