Procurement is aerospace’s new frontier-merging technology, precision, and foresight to power a connected supply ecosystem.

A few years ago, procurement in aerospace was a quiet, behind-the-scenes function. Today, it’s sitting right on the flight deck of strategy. The aerospace supply chain has become one of the most complex networks in modern industry.

From high-precision parts to global regulatory compliance, procurement managers now operate in a constant balancing act between cost, quality, availability and accountability.

McKinsey’s 2024 analysis found that aerospace supply chain health declined 9% between 2020 and 2023, one of the sharpest drops of any manufacturing sector. That statistic tells a bigger story: procurement isn’t just about buying parts anymore. It’s about building resilience.

Source: McKinsey & Company – Overcoming Challenges in Aerospace Procurement

Why Procurement Has Become So Challenging

Procurement in aerospace sits at the intersection of precision engineering, strict regulation, and global dependency. Every component-from turbine blade to titanium bolts must meet stringent safety and traceability standards like AS9100 and FAA certifications.

But technical precision is only half the challenge. Today’s procurement leaders face five overlapping pressures that make decision-making harder than ever:

- Regulatory intensity – Constant audits, ESG mandates and defense-specific approvals create continuous oversight cycles.

- Supply fragility – Tier 2 and Tier 3 suppliers, often small and specialized, remain financially stretched and capacity-constrained.

- Cost vs. precision tension – Finance pushes for savings, engineering demands perfection-and procurement stands in the middle.

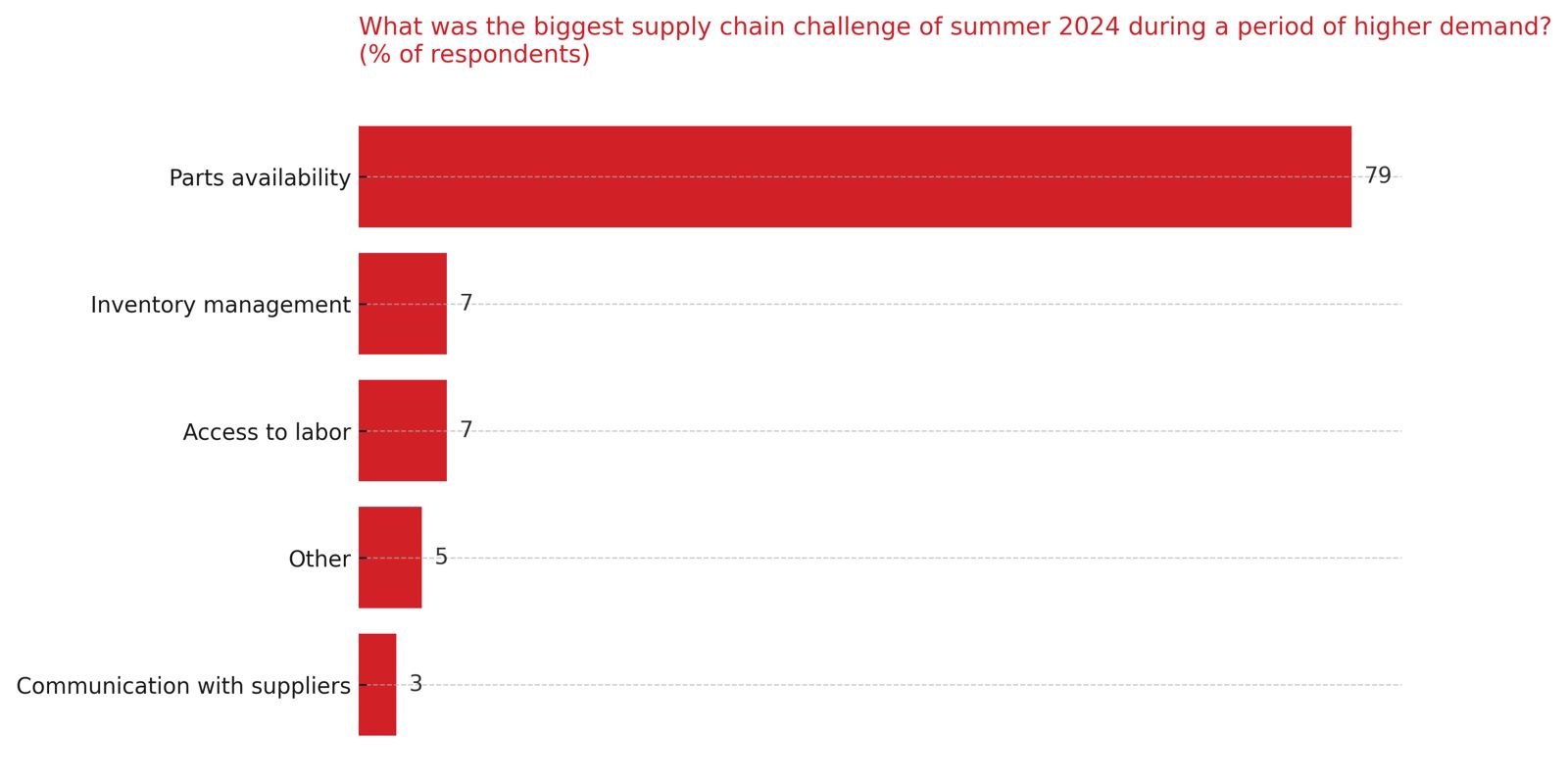

- Volatile lead times – Shortages in alloys, electronics, and castings can ripple across multi-year production programs.

- Talent and technology gaps – As veteran professionals retire, new talent must learn both legacy systems and digital tools.

Source: Kearney – Aerospace Supply Chain Resilience Through Collaboration

Every sourcing decision is now a strategic one-because even a minor delay can derail schedules, budgets and reputations.

Procurement as the Integrator

Procurement has become the connecting tissue of aerospace operations. It touches engineering for specifications, quality assurance for compliance, finance for budgets and operations for delivery schedules.

Kearney’s 2025 Aerospace Resilience Study found that companies with strong cross-functional collaboration recover twice as fast from supply disruptions. When procurement joins early in design and planning conversations, potential problems surface sooner. Specifications become realistic, sourcing options expand and risk is distributed more intelligently.

Yet, in many organizations, procurement is still looped in too late. The result? Delays, emergency sourcing and a cycle of reactive firefighting. The future of procurement will depend on breaking those silos-and replacing them with connected data and shared accountability.

Digital Transformation Takes Flight

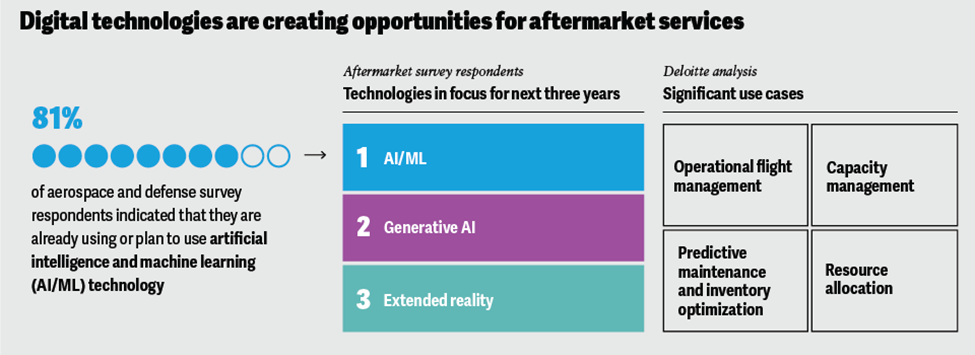

Technology is redefining what procurement in aerospace can do. AI, analytics, and cloud-based platforms are turning traditional sourcing into a predictive discipline-one where teams anticipate risk before it hits the assembly line.

AI and Predictive Analytics

Artificial intelligence can now analyze historical disruptions, supplier performance, and even external signals like shipping patterns or currency fluctuations to predict where trouble might emerge. EY’s 2024 study found that aerospace firms using predictive analytics reduced disruption response times by up to 40%.

Digital Procurement Platforms

Modern procurement platforms are breaking down the visibility gap. They integrate data from engineering, quality, and finance systems-giving teams a unified view of:

- Supplier reliability and certification status

- Lead-time and pricing trends

- ESG performance metrics

- Contract compliance and renewal alerts

These tools don’t replace people- they amplify their judgment. Procurement managers finally have real-time intelligence instead of outdated reports.

Simulation and Digital Twins

Digital twins-virtual models of supply networks are helping teams test “what-if” scenarios before they become crises. What happens if a casting plant in Europe shuts down? If nickel prices spike 20%? Simulation helps procurement make faster, data-driven adjustments with confidence.

Source: Deloitte – Aerospace & Defense Industry Outlook

From Savings to Strategic Capability

For decades, procurement’s success was measured in one word: savings. But in aerospace, that’s changing today, the focus is on stability, predictability, and strategic capability-ensuring programs run without disruption and suppliers are aligned to long-term goals.

Data transparency is also reshaping the dynamic between finance and procurement. When both teams see the same cost models and supplier analytics, the discussion moves from argument to alignment. Procurement can now show not just how much money was saved, but how much risk was avoided.

Sustainability adds another dimension. As Deloitte’s Aerospace & Defense Outlook 2025 notes, procurement is becoming the “sustainability gatekeeper,” embedding ESG compliance, carbon tracking, and ethical sourcing into everyday decisions. This evolution redefines value: from cost reduction to capability creation.

The Flightpath Ahead

The next generation of aerospace procurement will be data-driven, collaborative, and predictive. Roland Berger forecasts that by 2030, procurement intelligence will be as essential to competitiveness as design engineering itself. Tomorrow’s procurement manager will rely on live dashboards showing supplier health, digital simulations of disruption scenarios, and AI-driven sourcing recommendations. But technology alone won’t guarantee success.

What will matter most is mindset-moving from control to coordination, from reaction to foresight, from purchasing to partnership.

The organizations that master this shift will turn procurement into a source of strategic advantage-one that keeps aircraft programs on track, suppliers engaged, and innovation in motion.

Closing Thought

Precision built the aerospace industry. Prediction will shape its future.

Procurement teams are being asked to anticipate disruption, safeguard continuity, and accelerate innovation - all at the same time. Only connected systems and data-driven collaboration can make that possible. Aerospace procurement is entering a new era.

Sources:

- McKinsey & Company – Overcoming Challenges in Aerospace Procurement (2024)

- EY – How Can Digital Supply Chains Help Manage Aerospace Risk? (2024)

- Kearney – Aerospace Supply Chain Resilience Through Collaboration (2025)

- Deloitte – Aerospace & Defense Industry Outlook 2025

- Roland Berger – Aerospace Supply Chain Report 2025